Wood Plastic Composite (WPC) has emerged as a popular and innovative material in the construction and home improvement industry.

Known for its eco-friendly nature, durability, and versatility, WPC is finding its way into a wide range of applications, from decking and fencing to furniture and flooring.

As with any building material, understanding the factors that influence WPC price is essential for making informed decisions and ensuring the best value for money.

In this article, we will explore the various factors and considerations that affect WPC pricing, allowing consumers and builders to navigate the market with confidence.

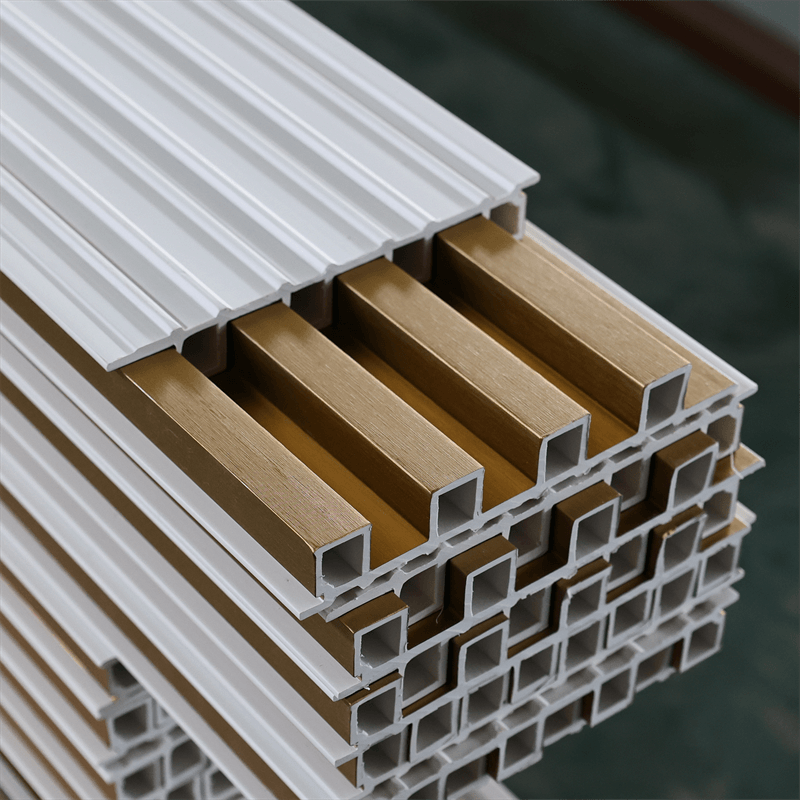

Raw Material Composition

The primary components of WPC are wood fibers or flour and thermoplastic resins.

The type and quality of these raw materials significantly impact the overall cost of WPC products.

High-quality wood fibers or flour sourced from sustainably managed forests often command a premium price,

as do premium-grade thermoplastic resins with superior properties.

Moreover, the ratio of wood to plastic content in the WPC mixture can also affect its price.

Products with a higher wood content may be more expensive due to the increased use of natural wood fibers.

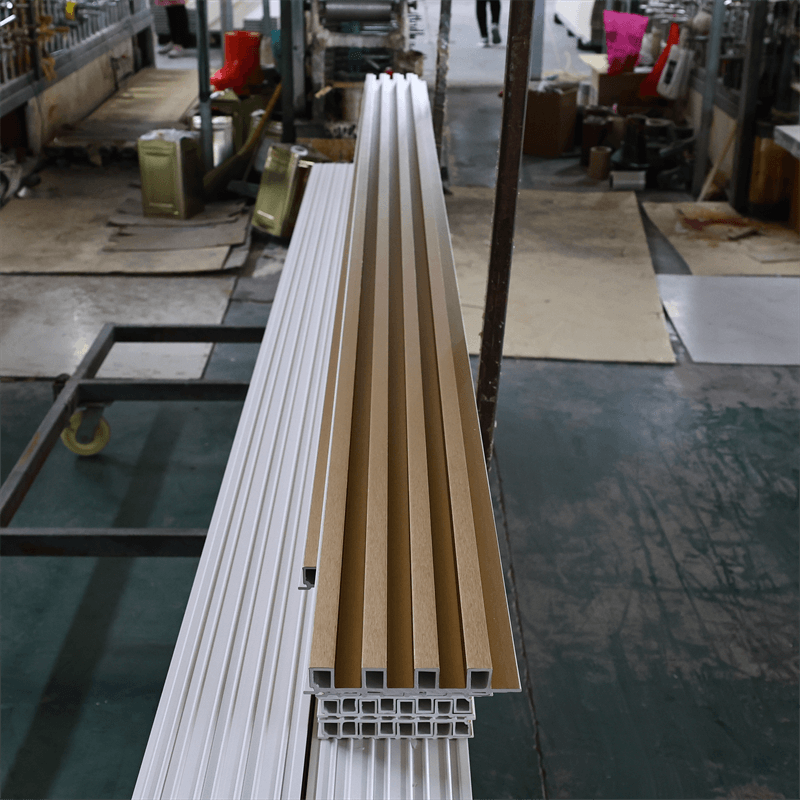

Manufacturing Process

The manufacturing process of WPC plays a vital role in determining its final price.

Advanced production techniques and technologies may increase the cost of WPC products compared to those manufactured using more conventional methods.

Additionally, the presence of additives or enhancements can contribute to the price variation.

Some WPC products may include additives such as UV stabilizers, colorants, and fire retardants,

which can add to the overall cost but enhance the performance and longevity of the material.

Quality and Performance

The quality and performance characteristics of WPC products can vary significantly across different manufacturers and brands.

Higher-quality WPC products that offer better resistance to moisture, UV rays, and wear are likely to come at a higher price point.

Consumers should consider the intended application and the performance requirements when evaluating WPC products.

Investing in higher-quality WPC with superior performance attributes can lead to long-term cost savings and improved durability.

Application and Design

The specific application and design requirements also influence the pricing of WPC products.

For instance, WPC decking designed for heavy traffic and outdoor use may be more expensive due to its enhanced durability and weather resistance.

Additionally, the aesthetic appeal of WPC products, such as color options, textures, and embossed patterns, can also affect their price.

Customized or specialty designs may command a premium.

Considerations for Choosing WPC Products

Budget and Affordability: Determine a budget for your project and look for WPC products that align with your financial considerations.

It is essential to strike a balance between quality and affordability.

Research and Compare: Take the time to research and compare various WPC products available in the market.

Look for product specifications, customer reviews, and warranties to make an informed decision.

Sustainability: Opt for WPC products made from responsibly sourced wood and eco-friendly thermoplastic resins.

Choose manufacturers that prioritize sustainable practices and environmental consciousness.

Performance: Consider the intended use and performance requirements of the WPC product.

Look for products that offer resistance to moisture, UV rays, and other environmental factors relevant to your project.

Longevity and Maintenance: Evaluate the expected lifespan and maintenance requirements of the WPC product.

Choosing a low-maintenance option can lead to long-term cost savings.

Understanding the factors that influence WPC price is crucial for making informed decisions in construction and home improvement projects.

The composition of raw materials, manufacturing processes, quality, and performance characteristics all play significant roles in determining the cost of WPC products.

When choosing WPC products, it is essential to strike a balance between quality, performance, and affordability.

Researching and comparing various WPC options available in the market will help consumers and builders find the best value for their investment.

By considering sustainability, performance, and longevity, one can make well-informed decisions and embrace the numerous benefits that WPC has to offer.