Wood Plastic Composite (WPC) wall panels have gained immense popularity in the construction industry due to their durability, versatility, and eco-friendly characteristics.

To fully appreciate the benefits and qualities of WPC wall panels, it is essential to understand the intricate manufacturing process involved.

This essay aims to provide a comprehensive overview of the manufacturing process of WPC wall panels, delving into the materials used, the production techniques employed, and the environmental implications of this process.

I. Raw Materials: The Blend of Wood Fibers and Plastic

The manufacturing process of WPC wall panels begins with the careful selection of raw materials.

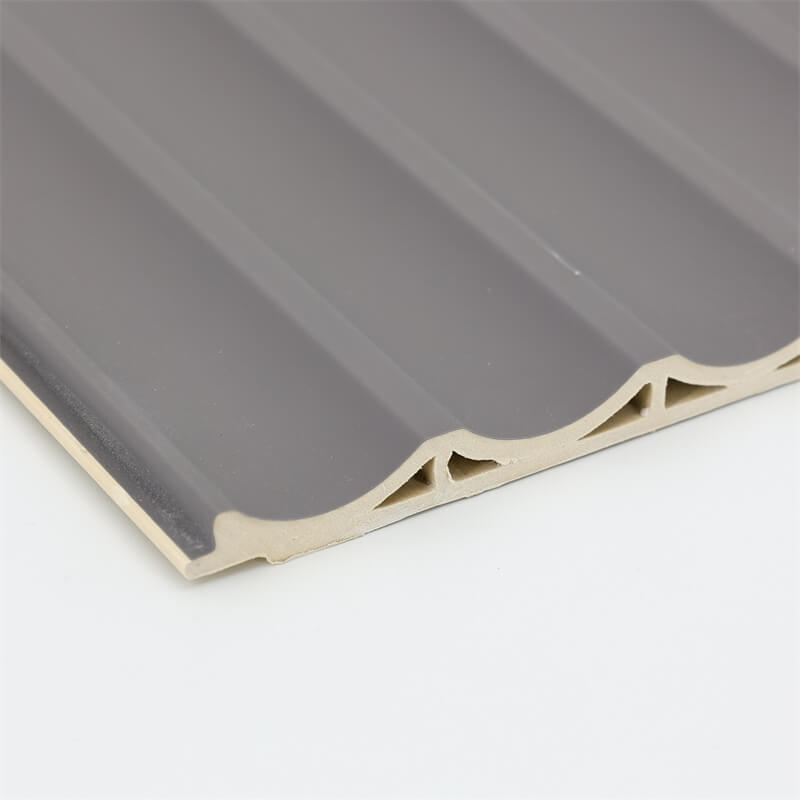

Wood fibers, typically sourced from reclaimed or recycled wood, are combined with plastic polymers, such as polyethylene (PE), polypropylene (PP), or polyvinyl chloride (PVC).

The wood fibers provide strength, structure, and natural aesthetics, while the plastic polymers enhance the durability, weather resistance, and moisture resistance of the final product.

II. Mixing and Blending: Achieving Homogeneous Composition

The next step in the manufacturing process involves the mixing and blending of the wood fibers and plastic polymers.

In this stage, the wood fibers and plastic pellets are combined in precise proportions to achieve a homogeneous mixture.

This blending process can be performed using various techniques, including extrusion, compounding, or injection molding, depending on the specific manufacturing equipment and desired product characteristics.

III. Extrusion: Shaping the WPC Wall Panels

Extrusion is the primary process used to shape the WPC wall panels.

The blended mixture from the previous stage is fed into an extruder, which consists of a rotating screw within a heated barrel.

As the mixture is pushed forward through the extruder, it undergoes high heat and pressure, causing the plastic to melt and encapsulate the wood fibers.

The molten composite is then forced through a shaping die, where it takes the form of the desired profile or dimensions of the wall panel.

IV. Cooling and Cutting: Solidifying the Panels

After exiting the extruder, the freshly formed WPC wall panels undergo a cooling process to solidify their structure.

Cooling can be achieved through various methods, including air cooling or water cooling, depending on the specific production setup.

Once the panels have cooled and hardened, they are cut into the desired lengths using automated cutting machines or saws.

V. Surface Treatment and Finishing: Enhancing Aesthetics and Protection

Surface treatment and finishing play a crucial role in enhancing the aesthetics and protecting the WPC wall panels.

Various techniques can be employed during this stage, including embossing, sanding, or applying decorative overlays.

Embossing can mimic the texture and appearance of natural wood grains, while sanding can create a smooth and even surface.

Additionally, protective coatings or finishes can be applied to enhance the panels’ resistance to UV radiation, moisture, and color fading.

VI. Environmental Considerations: Promoting Sustainability

The manufacturing process of WPC wall panels presents certain environmental considerations.

On the positive side, the utilization of recycled or reclaimed wood fibers helps reduce waste and minimize deforestation.

Additionally, the durability and longevity of WPC wall panels contribute to a longer lifespan compared to traditional materials, reducing the need for frequent replacements and associated environmental impact.

However, it is important for manufacturers to ensure proper waste management and adhere to environmentally responsible practices, such as energy-efficient production methods and recycling or reusing production waste.

The manufacturing process of WPC wall panels involves a precise combination of wood fibers and plastic polymers, shaping them through extrusion, and applying surface treatments and finishes.

This process results in a versatile and durable material that offers numerous advantages over traditional wall cladding options.